Davis field replaced, football team adapts

Davis Field took six weeks to replace, finishing a week before the football team’s first game. The new field has a more eco-friendly, natural infill consisting of cork, sand, and coconut husk.

August 31, 2018

For the past decade, the vast majority of school events, from Homecoming to spirit rallies to fire drills, have taken place on Davis Field. However, this very well-used field was beginning to near its end: its turf was beginning to wear down and become unattached to the ground, finding its way into students’ shoes, hair and everything in between. It was time for the field to receive a makeover.

The aging 11-year-old Davis field was replaced over the summer with a new and improved field. The entire removal and reinstallation process took about six weeks to complete.

In addition to simply replacing the weathering field, the new surface of turf contains more natural components than its predecessor.

“We didn’t go with the crumb rubber […] but instead, we went with the more natural infill,” athletic director Dan Molin said. “It’s a combination of sand, cork, and coconut husk, which is better for sustainability.”

Besides the sustainability advantage, the new materials in the infill have a lower specific heat capacity than the traditional rubber pellets, allowing the field to dissipate heat faster, and thus be cooler by the time the players go to practice. The field can be as much as 25 degrees Fahrenheit cooler than the crumb rubber alternative, decreasing player fatigue.

Other new features include the three-inch padding under the field, three-quarters of an inch thicker than the previous field, with the extra thickness occupied by a layer of compressed foam known as “Pro Play.” In addition to providing a more forgiving playing surface, this layer of foam has the added benefit of absorbing water, improving the drainage capabilities of the field.

“We chose a quality system, that should last for 12 years or longer and remain cost-effective,” facility director Mike Bassoni wrote during an email interview.

A close-up picture displaying the coconut husk-based infill of the new Davis Field. The new materials in the infill have a lower specific heat capacity than the traditional rubber pellets, allowing the field to dissipate heat faster, and thus be cooler by the time the players go to practice.

The whole project cost $587,585, or about $7.80 per square foot of field.

However, while the field was undergoing replacement, the football team has had to adapt, holding practice on the Blackford fields instead.

“The first week of us practicing on Blackford field was a little rough just because we weren’t used to practicing on a grass field,” varsity offensive and defensive lineman Nicholas Coulter (10) said. “It’s not as great of a field as Davis, but as the weeks went on, we just put that in the back of our minds.”

However, the field was ready just in time — a week before — for the game against Saratoga High on Aug. 17.

“It’s definitely amazing,” offensive and defensive lineman and varsity captain Ayush Vyas said. “After playing on [the Blackford field], you definitely appreciate everything you have. It just makes us a lot more understanding and […] not complacent.”

This piece was originally published in the pages of The Winged Post on Aug. 31, 2018.

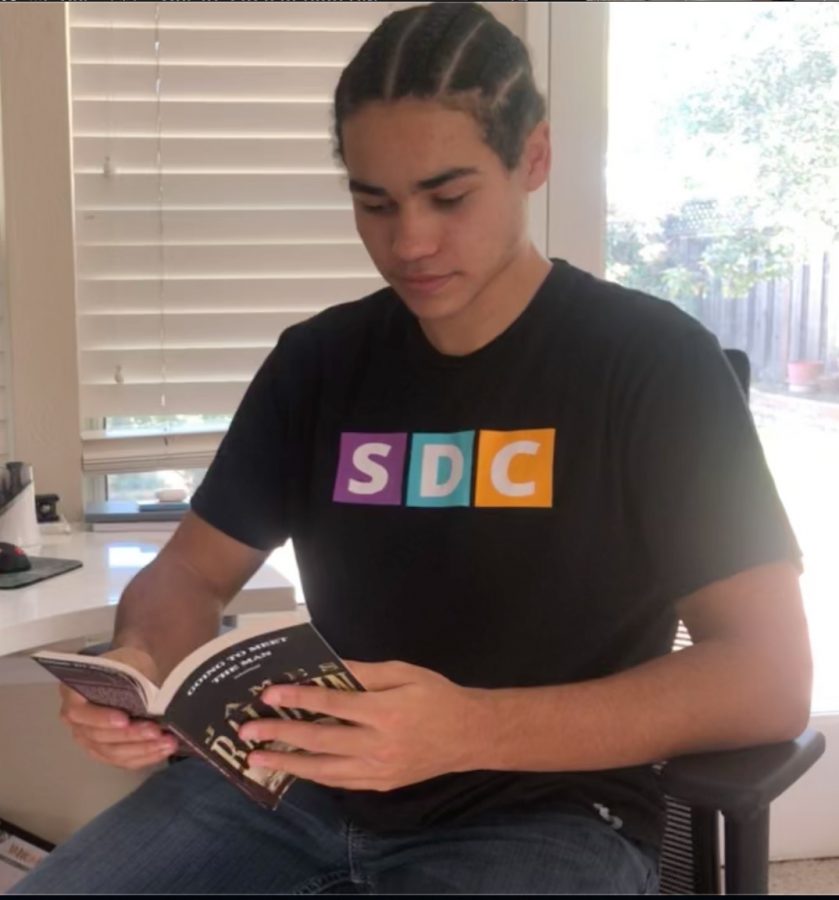

![“[Building nerf blasters] became this outlet of creativity for me that hasn't been matched by anything else. The process [of] making a build complete to your desire is such a painstakingly difficult process, but I've had to learn from [the skills needed from] soldering to proper painting. There's so many different options for everything, if you think about it, it exists. The best part is [that] if it doesn't exist, you can build it yourself," Ishaan Parate said.](https://harkeraquila.com/wp-content/uploads/2022/08/DSC_8149-900x604.jpg)

![“When I came into high school, I was ready to be a follower. But DECA was a game changer for me. It helped me overcome my fear of public speaking, and it's played such a major role in who I've become today. To be able to successfully lead a chapter of 150 students, an officer team and be one of the upperclassmen I once really admired is something I'm [really] proud of,” Anvitha Tummala ('21) said.](https://harkeraquila.com/wp-content/uploads/2021/07/Screen-Shot-2021-07-25-at-9.50.05-AM-900x594.png)

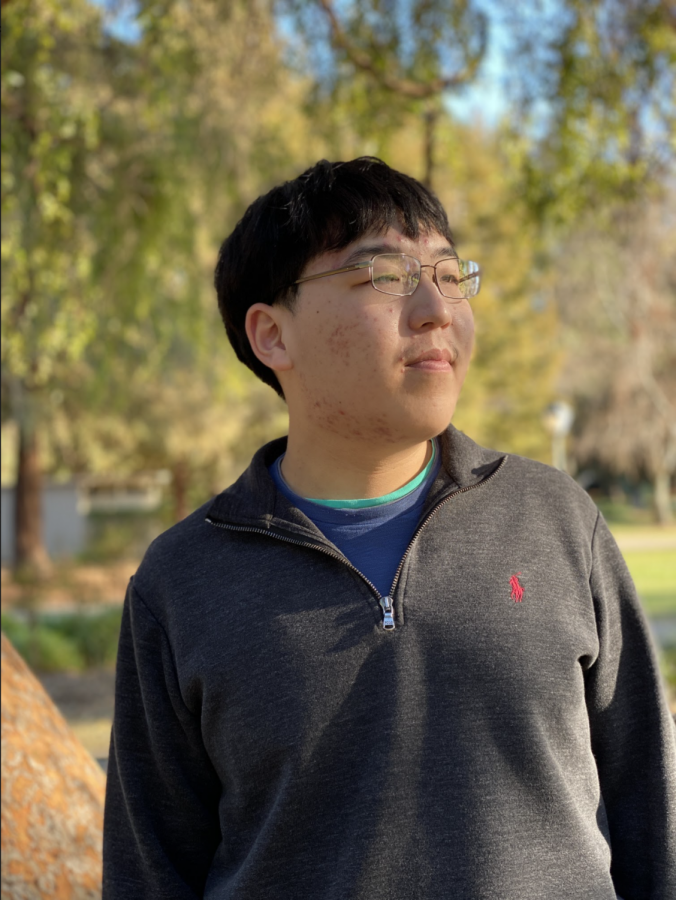

![“I think getting up in the morning and having a sense of purpose [is exciting]. I think without a certain amount of drive, life is kind of obsolete and mundane, and I think having that every single day is what makes each day unique and kind of makes life exciting,” Neymika Jain (12) said.](https://harkeraquila.com/wp-content/uploads/2017/06/Screen-Shot-2017-06-03-at-4.54.16-PM.png)

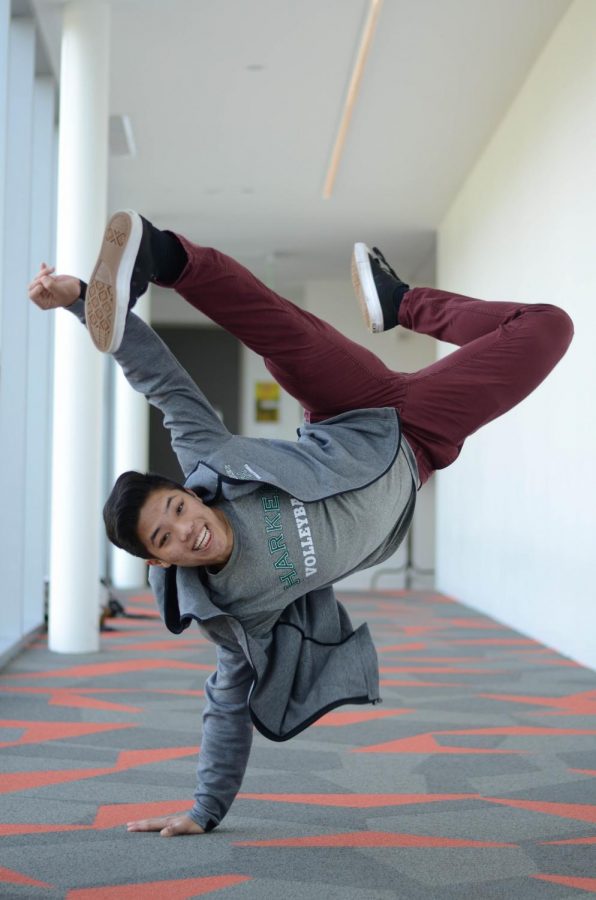

![“My slogan is ‘slow feet, don’t eat, and I’m hungry.’ You need to run fast to get where you are–you aren't going to get those championships if you aren't fast,” Angel Cervantes (12) said. “I want to do well in school on my tests and in track and win championships for my team. I live by that, [and] I can do that anywhere: in the classroom or on the field.”](https://harkeraquila.com/wp-content/uploads/2018/06/DSC5146-900x601.jpg)

![“[Volleyball has] taught me how to fall correctly, and another thing it taught is that you don’t have to be the best at something to be good at it. If you just hit the ball in a smart way, then it still scores points and you’re good at it. You could be a background player and still make a much bigger impact on the team than you would think,” Anya Gert (’20) said.](https://harkeraquila.com/wp-content/uploads/2020/06/AnnaGert_JinTuan_HoHPhotoEdited-600x900.jpeg)

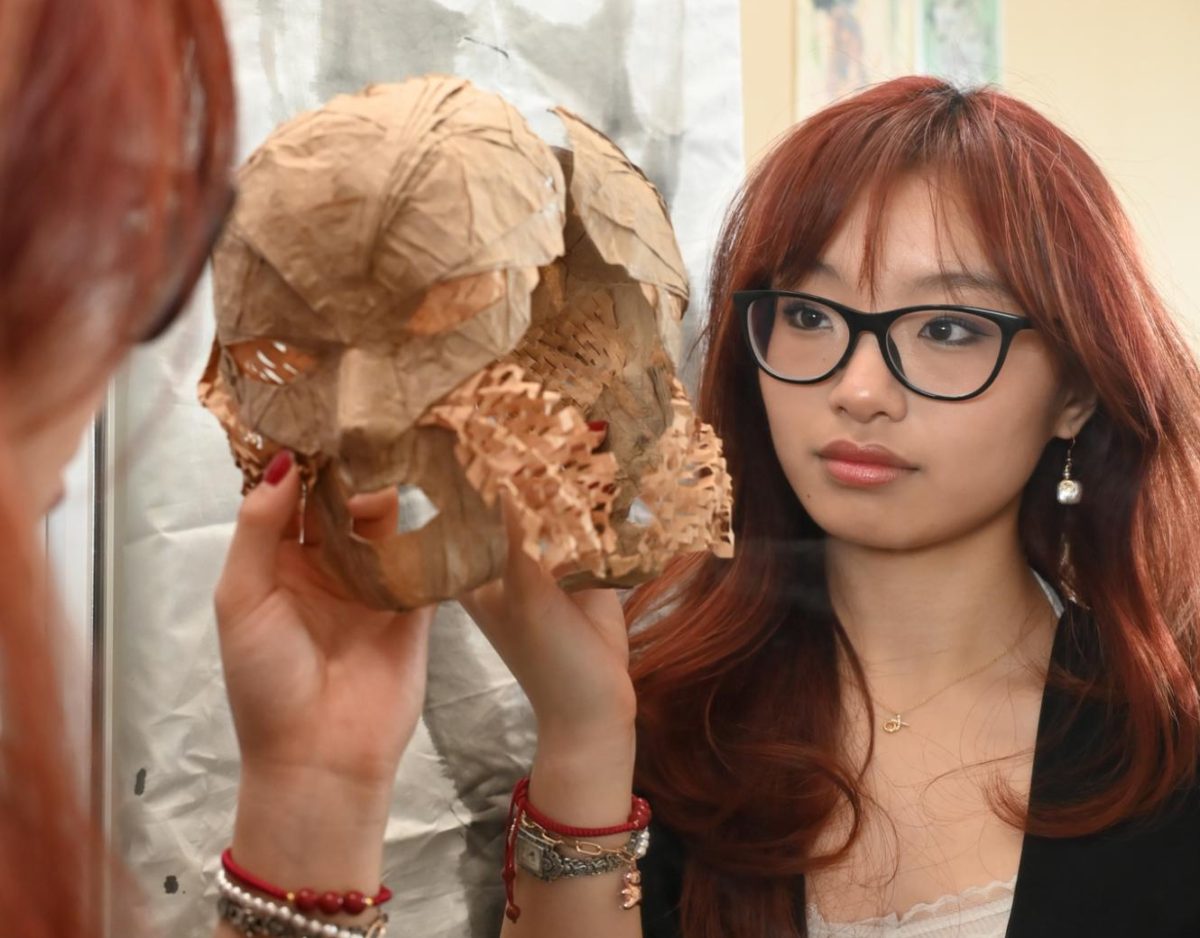

![“I'm not nearly there yet, but [my confidence has] definitely been getting better since I was pretty shy and timid coming into Harker my freshman year. I know that there's a lot of people that are really confident in what they do, and I really admire them. Everyone's so driven and that has really pushed me to kind of try to find my own place in high school and be more confident,” Alyssa Huang (’20) said.](https://harkeraquila.com/wp-content/uploads/2020/06/AlyssaHuang_EmilyChen_HoHPhoto-900x749.jpeg)