Inside the New York Times printing press

The printing presses at College Point print three versions of an issue every night. The first issue, Part 1, goes to the farthest points of distribution. Part 2 stays a little closer, and the latest version travels the least. The company also rents out over 20 printing presses around the country to facilitate the printing and distribution of its National Edition, which can be found around the country.

Despite printing over 300,000 copies a day, the number of newspapers the facility has printed has actually decreased over the last few years. Meanwhile, the number of online subscriptions has jumped to almost 700,000.

The tour guide, Ernie Booth, the Manager of Productions Operations, began the tour by explaining what happens if weather conditions, breaking news, or other unforeseen circumstances call for a change in the paper or make distribution and production difficult.

“[For weather], we’ll have earlier closes,” he said. “We’ll go to the editorial department, and we’ll say ‘it’s going to snow,’ and they’ll give us an earlier close, and we’ll finish printing maybe around 1 a.m. in the morning or so.

He remembered certain instances such as a fire that took place or a power outage that made printing the papers more difficult. 9/11, for example, made distributing all of the papers a challenge and special actions had to be taken.

“We printed that night one million copies,” he said. “Because all the bridges were shut down, we called the mayor and we called the governor to escort our papers into Manhattan. That was quite an experience for us that night, and it was a reminder of how vulnerable as a country we were, but we were able to get the paper out.”

Each night, workers from 9 different unions come together to finish printing the paper, making it important to minimize strikes. In order to do this, the workers and managers maintain a friendly environment and work quickly to negotiate when disputes erupt.

The factory emphasizes quality because a minor error can cost the New York Times tens of thousands of dollars. When errors like this occur, the money is taken from the workers’ bonuses, which increases the incentive for the employees to maintain as high a quality standard as possible.

For the Upper School journalists, the tour showed the amount of work that goes into the print product they are so used to making after they send it off to be printed.

“Seeing this facet of the New York Times and how the paper actually comes alive changed my perspective of the impact of my job as a section editor for The Winged Post,” Global Editor Sindhu Ravuri (11) said. “After witnessing the sheer effort and immense process that goes into the printing process, I feel honored that there are countless numbers of people who work so assiduously to make my work as vivid as it is. It made me feel that I need to ensure each part of my paper is that much better.”

Journalism advisor Ellen Austin was impressed by the automation of the entire process.

“I had a moment where I was thinking how few people could you have in here and hit a switch and have The New York Times’ 300,000 copies get printed…2? 5? 8? I don’t know, that was pretty neat,” she said. “I was blown away by the passion and enthusiasm the people who were showing us around had for it. It was clear that the New York Times isn’t just cool to read, but a cool place to be.”

Pressmen and night-shift managers often spend most of the night working, sometimes between 5 p.m. and 3.30 a.m. the next morning depending on how quickly the paper is printed.

“We don’t sleep anymore. I’m nocturnal,” Ernie said. Really, actually what I do is I take naps. I’ll work tonight and get off depending on when the presses get off, if the presses get off around 3:30 then i’ll go home around 4 and take a nap and get up and do conference calls. I’ve been working nights for about 25 years, and I enjoy it. it becomes a part of you. This is a really exciting job. There is always something different.”

Alyssa Amick (12) is the Co- Editor in Chief of Harker Aquila. She has been part of the journalism program since her freshman year. Her favorite part of...

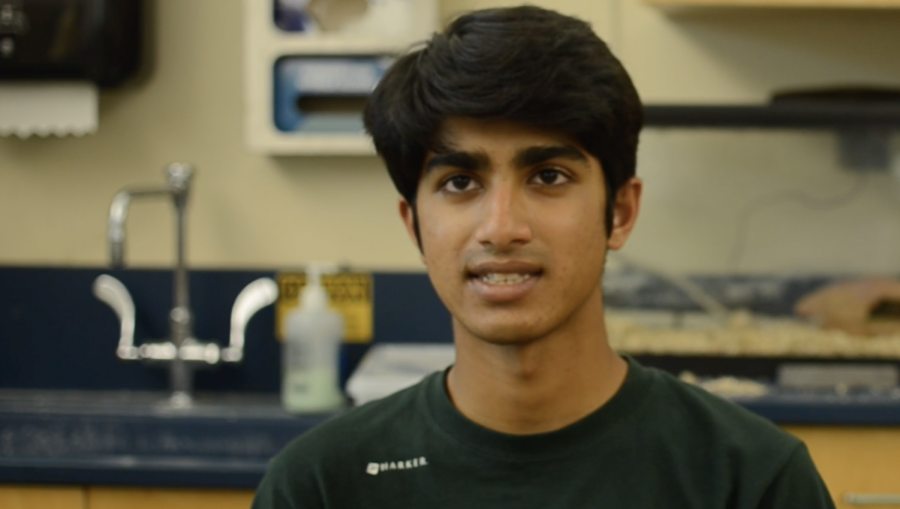

![“[Building nerf blasters] became this outlet of creativity for me that hasn't been matched by anything else. The process [of] making a build complete to your desire is such a painstakingly difficult process, but I've had to learn from [the skills needed from] soldering to proper painting. There's so many different options for everything, if you think about it, it exists. The best part is [that] if it doesn't exist, you can build it yourself," Ishaan Parate said.](https://harkeraquila.com/wp-content/uploads/2022/08/DSC_8149-900x604.jpg)

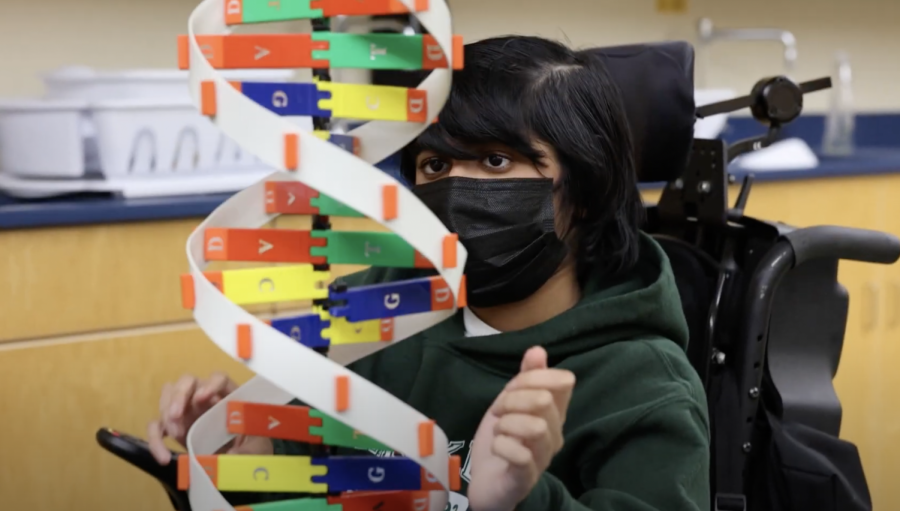

![“When I came into high school, I was ready to be a follower. But DECA was a game changer for me. It helped me overcome my fear of public speaking, and it's played such a major role in who I've become today. To be able to successfully lead a chapter of 150 students, an officer team and be one of the upperclassmen I once really admired is something I'm [really] proud of,” Anvitha Tummala ('21) said.](https://harkeraquila.com/wp-content/uploads/2021/07/Screen-Shot-2021-07-25-at-9.50.05-AM-900x594.png)

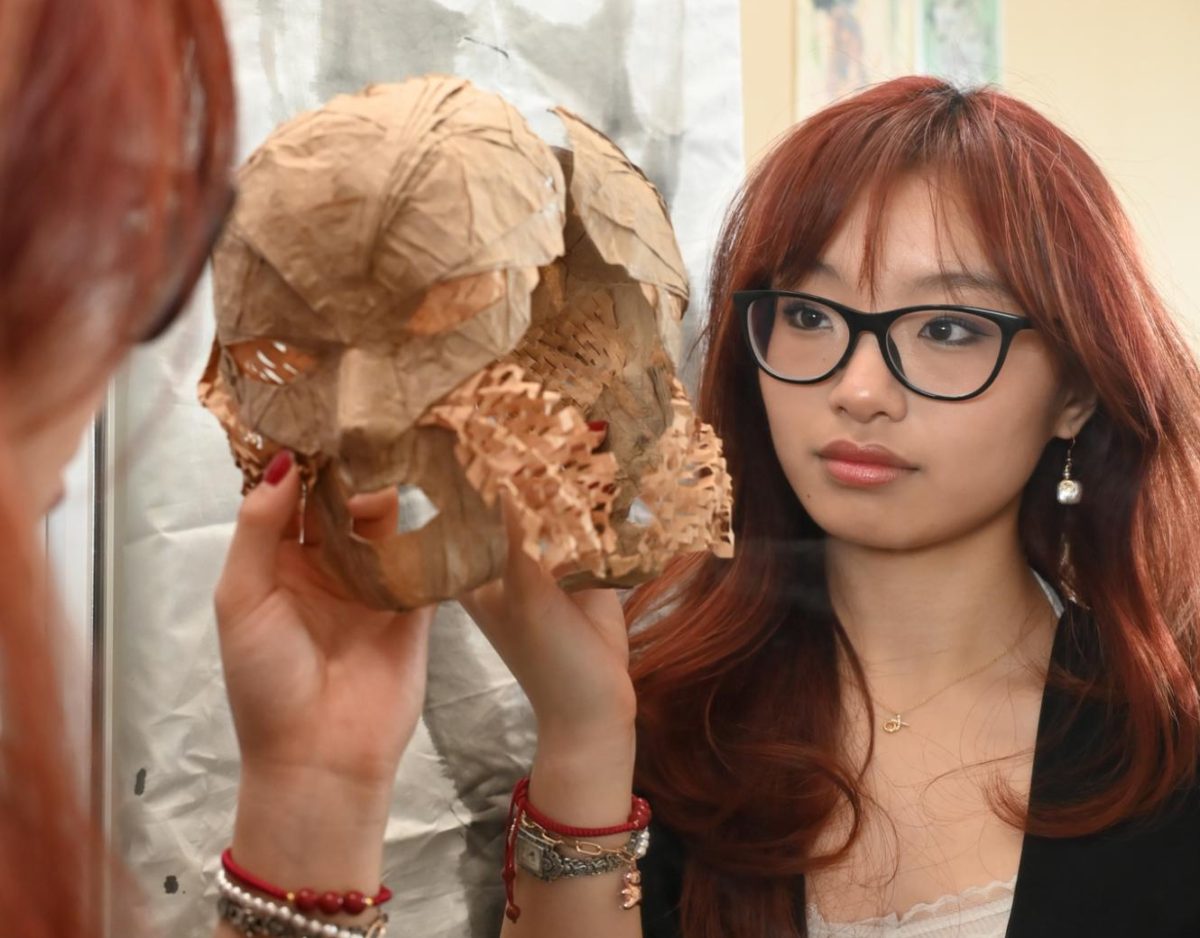

![“I think getting up in the morning and having a sense of purpose [is exciting]. I think without a certain amount of drive, life is kind of obsolete and mundane, and I think having that every single day is what makes each day unique and kind of makes life exciting,” Neymika Jain (12) said.](https://harkeraquila.com/wp-content/uploads/2017/06/Screen-Shot-2017-06-03-at-4.54.16-PM.png)

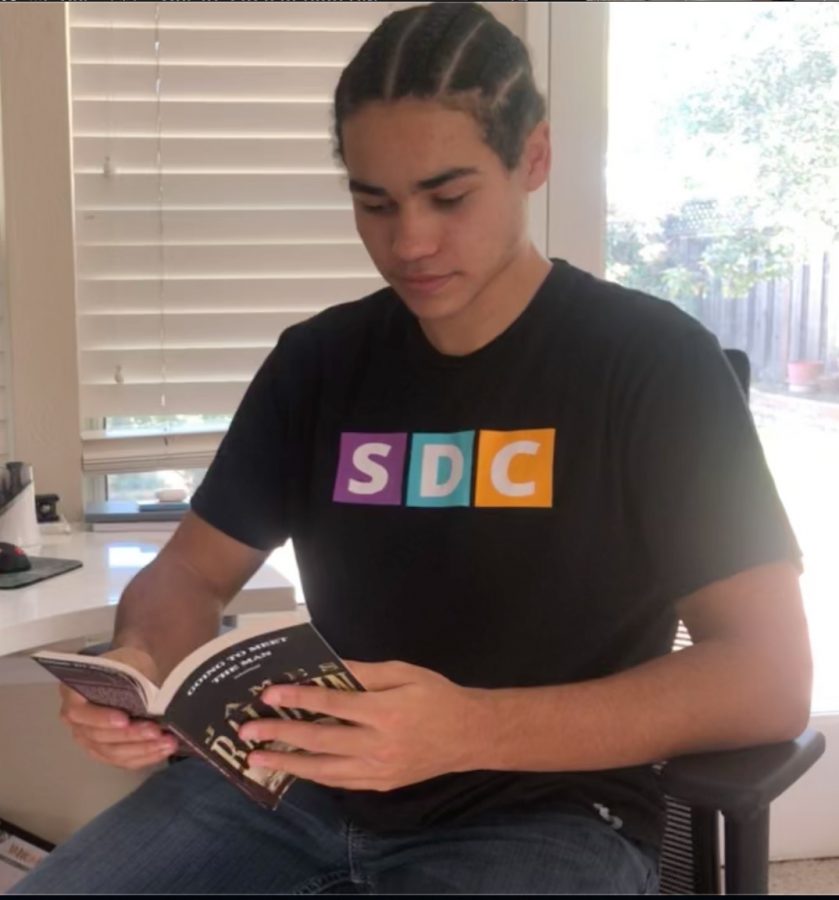

![“My slogan is ‘slow feet, don’t eat, and I’m hungry.’ You need to run fast to get where you are–you aren't going to get those championships if you aren't fast,” Angel Cervantes (12) said. “I want to do well in school on my tests and in track and win championships for my team. I live by that, [and] I can do that anywhere: in the classroom or on the field.”](https://harkeraquila.com/wp-content/uploads/2018/06/DSC5146-900x601.jpg)

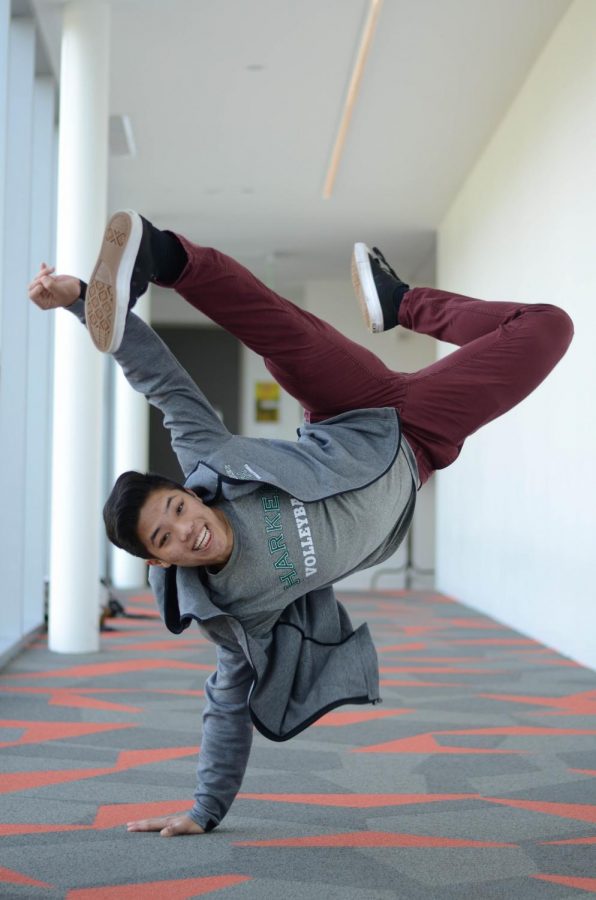

![“[Volleyball has] taught me how to fall correctly, and another thing it taught is that you don’t have to be the best at something to be good at it. If you just hit the ball in a smart way, then it still scores points and you’re good at it. You could be a background player and still make a much bigger impact on the team than you would think,” Anya Gert (’20) said.](https://harkeraquila.com/wp-content/uploads/2020/06/AnnaGert_JinTuan_HoHPhotoEdited-600x900.jpeg)

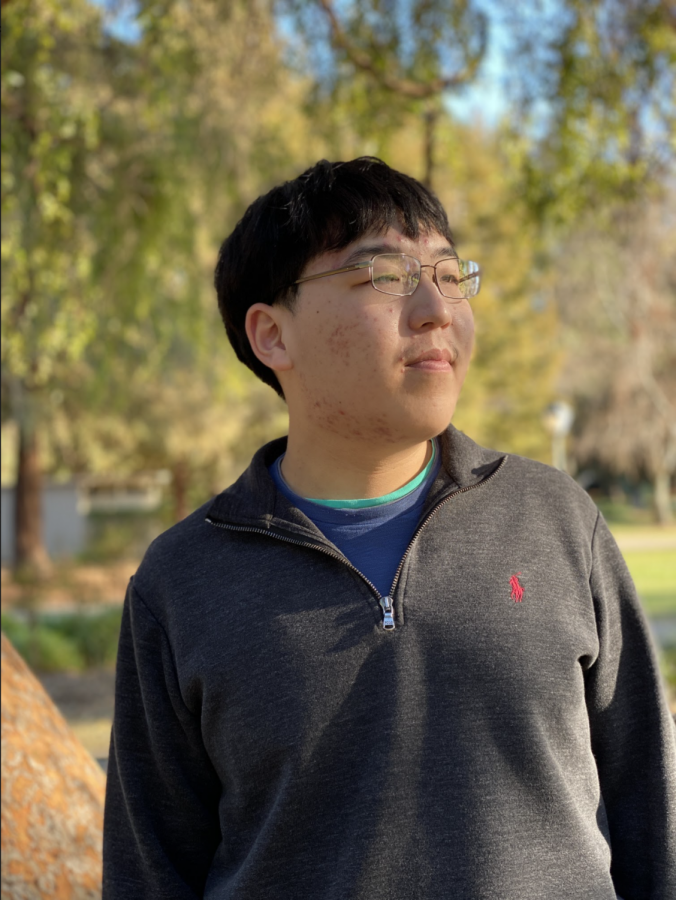

![“I'm not nearly there yet, but [my confidence has] definitely been getting better since I was pretty shy and timid coming into Harker my freshman year. I know that there's a lot of people that are really confident in what they do, and I really admire them. Everyone's so driven and that has really pushed me to kind of try to find my own place in high school and be more confident,” Alyssa Huang (’20) said.](https://harkeraquila.com/wp-content/uploads/2020/06/AlyssaHuang_EmilyChen_HoHPhoto-900x749.jpeg)